- A trusted supplier of lab equipment for over 35 years

UV-DUCT-SQ Germicidal

NATA-accredited calibration services

Guarantee the accuracy of your instruments with NATA-accredited calibration performed by qualified professionals.

NATA-accredited testing services

Benefit from NATA-accredited testing services that provide independent verification of your equipment’s performance.

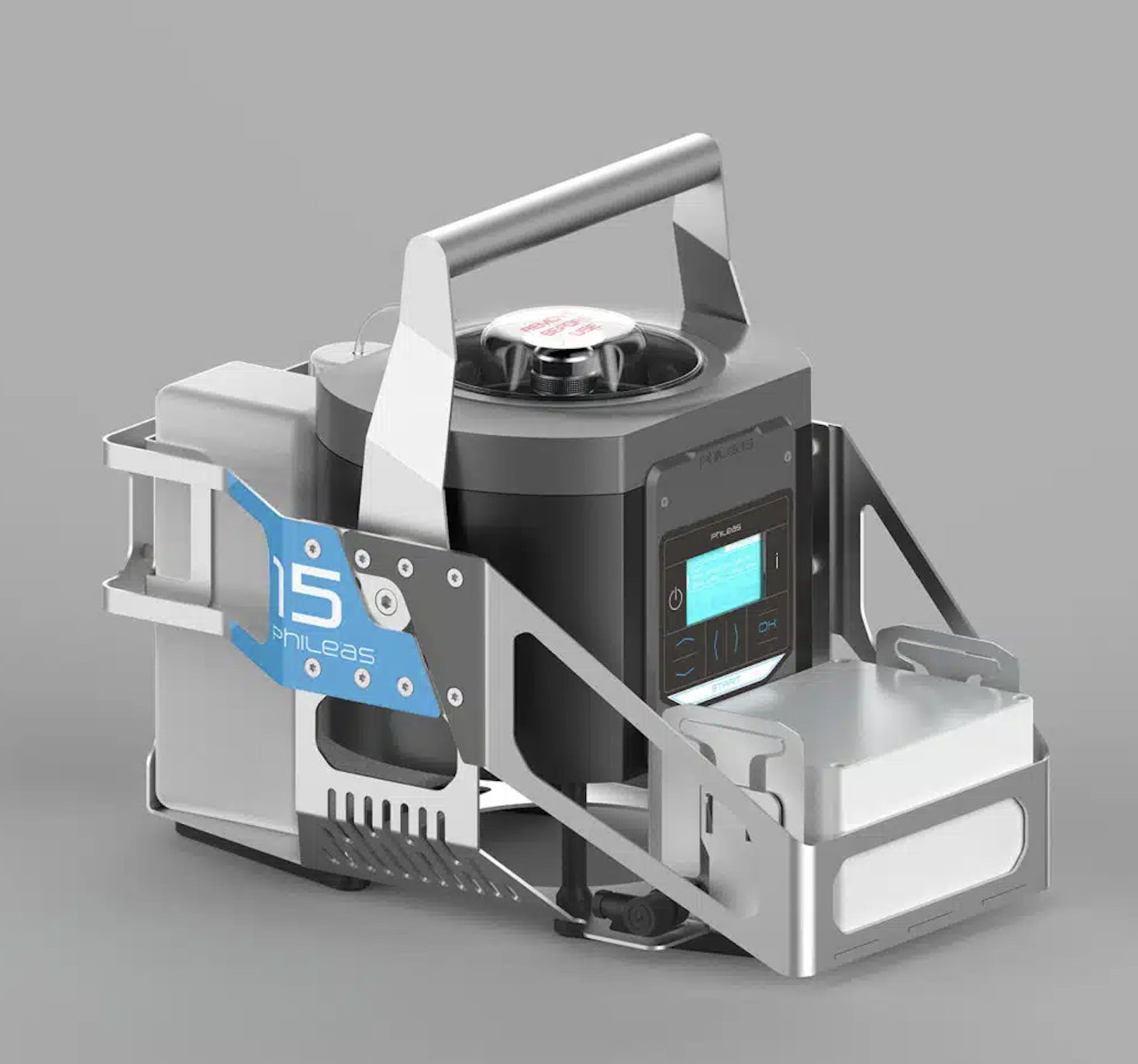

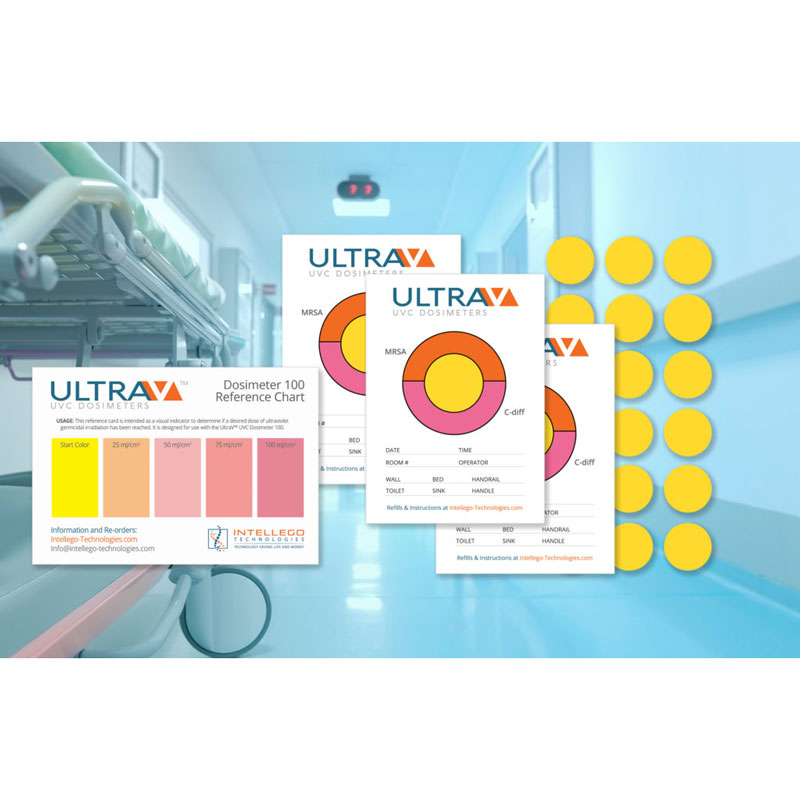

Bio-Decontamination

Maintain a safe and sterile laboratory environment with expert bio-decontamination services.

Environmental Monitoring Systems

Clean Room and Laboratory environmental monitoring system projects and technical support

IOQ (Installation Operational Qualification) services

Verify the proper installation and functionality of your equipment with IOQ services.

Commissioning & validation services

Ensure your equipment is properly installed, qualified, and meets performance specifications through commissioning and validation services.

Book a service technician online now

Looking to book a LAF tech service technician for repairs, calibration testing and/or maintenance? Complete our online booking form.

- Our Products

Bugbox

Bugbox Anaerobic Workstation. Baker’s anaerobic workstations are engineered specifically to help microbiologists cope with rising workloads and provide the best primary isolation rates.

UV-STICK Portable Germicidal

UV STICK E2/75H-ST-NX-NT is a commercial grade dual lamp germicidal device with control timer panel and four wheels for easy mobility.

Purair Advanced Ductless Fume Hoods

Our Purair advanced series of ductless fume hoods are a series of high efficiency products designed to protect the user and the environment from hazardous vapors generated on the work surface.

Lighthouse Automated Microbial Monitoring Systems

LIGHTHOUSE designed the Remote Active Count system to meet the industry need for continuous trouble-free operation and flexible running parameters.

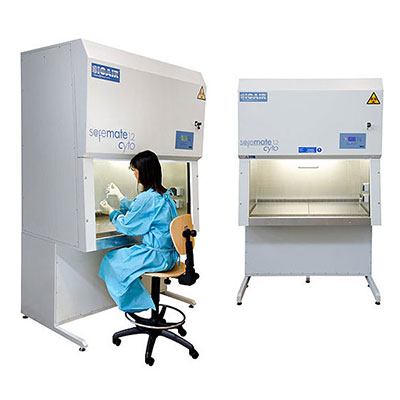

Safemate CYTO Cytotoxic Cabinets

BioAir Safemate CYTO Cytotoxic Drug Handling Cabinets LAF Technologies is the exclusive Australian agent for BioAir and their world renowned range of professional cytotoxic cabinets.

TEC PH-4 Precision Aerosol Photometer

PH-4 digital photometer is world’s most compact and advanced digital Aerosol Photometer utilised for testing HEPA filters.

Safekeeper Evidence Drying Cabinets

Safekeeper Forensic Evidence Drying Cabinets Evidence Drying Cabinets for Industry Professionals LAF Technologies is one of Australasia’s leading suppliers of latest generation forensic evidence drying cabinets and other specialist forensic equipment.

General Incubators

JSR General Incubators offer a versatile solution for controlled-temperature incubation needs. These programmable incubators, available in chamber volumes ranging from 50 to 250 litres, provide precise temperature control from ambient +5°C to +70°C.

Electric Muffle Furnace – Max. 1,100 oC

Ideal for experiments and process needs high temperature up to 1,100 oC such as chemical analysis, annealing loss determination, materials testing and ashing processes. Laftech Bio-Cabinets supply quality lab equipment and products throughout Australia.

HF Series Spark Free Freezer

Temperature Range -18°C to -22°C, Bottom Mounted System, Solid Door, Capacity: 125L, 350L, 570L

-20 Deg C Refrigerated Circulation Baths

Our heated / refrigerated circulating open bath systems are capable of reaching temperatures as low as -20 oC and heating up to + 120 oC for a wide variety of laboratory heating and cooling applications.