UV-C Disinfection Systems & Devices

ULTRAVIOLET SOLUTIONS FOR CONTAMINATION CONTROL AND SURFACE TREATMENT

UV RAYS and Environmental Disinfection

UV-C rays: reliable technology

Why is room disinfection important?

Cleaning, Disinfection, Sanitization and Sterilization

Are UV rays reliable and effective for disinfection?

Do bodies and organizations recommend the use of UV-C rays?

What are the areas of use for UV rays?

What are the advantages of Light Progress products for environmental disinfection?

Permanent direct radiation in the absence of people – UV STICK

Direct irradiation in the absence of people on wheels – UV STICK-ST

Direct radiation in the absence of people on wheels – UV PENTALIGHT

Direct irradiation in the absence of people – University tests

Air purifiers in the presence of people – local treatment – UV FAN

Air purifiers local treatment and surface disinfection – UV FAN BD and UV FAN BD ST

Our UV-C Disinfection products and devices

-

UV-FAN-XS Germicidal

-

UV-STYLO-F Germicidal

-

UV-Cabinet Germicidal

-

UV-REFLEX Germicidal

-

UV-DUCT-SQ Germicidal

-

UV-STICK-AL-SCR Germicidal

-

UV-STICK-NX-SCR Germicidal

-

UV-BOX Table Top Germicidal

-

UV-FLOW Germicidal

-

UV-DUCT-FL Germicidal

-

UV-DIRECT Germicidal

-

UV-STICK Portable Germicidal

-

UV-FAN Germicidal

-

UV-BOX (Dual Shelf) Germicidal

-

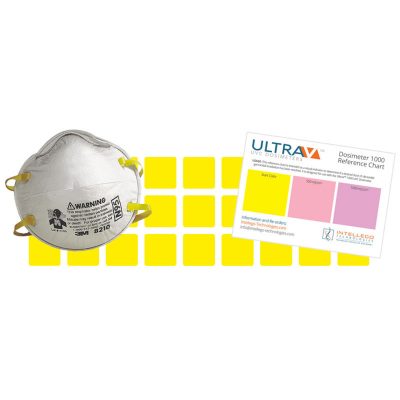

UltraV 1000 Dosimeters

-

UltraV 100 Dosimeters

UV rays and environmental disinfection

UV-C Rays = Reliable Technology

UV-C rays work mainly by destroying DNA or Rna inside bacteria, viruses and fungi.

UV-C light has been used for decades to disinfect industrial surfaces and sanitize

drinking water and is, in fact, particularly advantageous for sanitary use because it

eliminates microorganisms such as the bacterium Clostridium difficile, one of the

main sources of nosocomial infections .

UV-C technology has been used for the disinfection of air, water and tools for over a

century. It is therefore validated by history. In fact, as early as the 1930s, UV rays

were commonly used for the treatment of air and water in hospitals and, starting

from the Second World War, they were widely used in processing centers, in water treatment plants and in any facility that had to do with microbial contamination.

Light Progress, since 1987, uses UV-C rays as a solution for microbial decontamination, a technology that over the years has been recognized as synonymous with efficacy and safety.

Remember to avoid exposure to the light emitted by the ultraviolet lamp in order not to risk:

• serious damage to the eyes and skin.

• to yellow plastic or painted surfaces.

Why is room disinfection important?

Environments play a significant role in disease transmission.

The latest tests carried out on the resistance of Sars-Cov-2 in different surfaces (steel, copper, cardboard, plastic) lead us to think that more attention should be paid to deep environmental disinfection, in any area, not just the hospital one.

New materials and new technologies are now being introduced in an attempt to reduce the environmental pathway of disease transmission. Ultraviolet disinfection of surfaces is proving to be one of the most decisive and easy to manage among the solutions on the market.

The use of UV rays is not intended as a substitute for normal manual cleaning activities, but as a physical and ecological alternative that allows for deeper disinfection. In combination with traditional methods it can make a substantial difference in contamination control.

Cleaning, Disinfection, Sanitization and Sterilization

CLEANING

Removal of dirt from a surface compatible with its correct conservation. There is no guarantee of safety with respect to viruses, fungi and bacteria.

DISINFECTION

Application of disinfectants, almost always of a chemical or physical nature (such as UV) which are capable of reducing, through destruction inactivation, the microbiological load present on objects and surfaces to be treated.

SANITIZATION

Intervention, based on the use of detergent chemicals, aimed at eliminating the contaminants that regular cleaning is unable to remove.

STERILIZATION

Total elimination of all forms of life. It occurs through particular processes, such as the use of saturated steam under pressure, fire or treatment at high temperatures.

If correctly used, UV rays can lead to abatement results close to sterilization, even if it is more correct to always speak of disinfection or high degree of disinfection.

Are UV rays effective and reliable for disinfection?

Absolutely yes: a correct use of UV rays allows the elimination of up to 99.999% of microorganisms, such as bacteria and viruses, with extreme simplicity and practicality.

Lately their popularity has increased as they disinfect practically all surfaces of a room with minimal effort and without the use of hazardous chemicals or gases. After carrying out the treatment cycle necessary for disinfection, the rooms are immediately reusable in absolute safety and without any precaution as the UV rays do not leave any residue or substances circulating in the air and on the surfaces.

What organizations recommend the use of UV-C rays?

Many world-class bodies and organizations such as WHO, EPA, CDC, ASHRAE have been recommending the use of UV-C rays for the disinfection of water, environments and air conditioning systems for decades. The use of UV-C rays is also indicated for the prevention of Coronavirus Sars-Cov-2 and, following the recent COVID-19 pandemic, it has been successfully introduced in widely affected countries such as China, with examples that include hospitals, urban transport or even domestic environments.

What are the areas of use for UV rays?

There are no limits to the possible applications of UV-C rays, however specific skills are required to use this technology in an adequate way, obtaining maximum results. UV rays are used every day at:

PHARMACEUTICAL MANUFACTURING

To disinfect air and surfaces production environments, disinfect the containers of products (packaging), isolate “protected” areas for the production and the product packaging, like the clean rooms, from areas at risk of contamination. Interventions of this type increase significantly security and conservation of the products we buy commonly.

HEALTHCARE

To avoid the transmission of dangerous bacteria or viruses that may be present in the air or transported by contact by patients or visitors, such as the TB, Legionella, Sars and the new Covid-19. The sanitary field is historically the one with the most application examples, from air treatment to that of surfaces.

HVAC

To avoid the transmission of any partogen into the air, but also to prevent the formation of mold and bacterial colonies inside the air treatment plants in the pipes. Air conditioning is responsible for “building-related diseases”, allergic alveolitis, virus and fungus infections, bronchial asthma, humidifier fever, legionellosis, etc. Many armies have UV-C systems to also prevent possible attacks biological (anthrax).

WATER TREATMENT SYSTEMS

To eliminate all microorganisms that may be present in the water from wells and cisterns. UV rays are traditionally used in most public aqueducts and are often mandatory after an activated carbon filter in water dispensers that are increasingly taking hold in cities to replace the use of bottled water.

ENVIRONMENTS DOMESTIC

To avoid the formation of mold on the walls, to remove mites, to keep the air healthy inside a room, to treat water. UV-C rays also manage to eliminate odors and grease deposits in industrial kitchens and are also used in catering, with the support of ozone emissions.

If correctly used, UV rays can lead to abatement results close to sterilization, even if it is more correct to always speak of disinfection or high degree of disinfection.

Which microorganisms can be eliminated with UV rays?

Each microorganism has its own particular resistance to UV rays. For a high-level killing of a microbial load, for some myrcorganisms a few seconds of irradiation are sufficient while for others it takes longer or, for the same time, greater UV power. The charge reduction is expressed as “Log Reduction”, 1 Log = 90% reduction, 2 Log = 99% 3 Log = 99.9% etc.

These just introduced are the essential factors to understand and use UV technology effectively:

-

Objective of the degree of reduction (Log Reduction)

-

UV dose necessary for the elimination of the target pathogen

-

UV power in play

-

Exposition time

-

Space (Geometry and Distance)

What is the UV dose?

UV rays are effective against any microorganism. Thanks to experimental tests, it has been possible over the decades to establish the resistance to UV radiation of each pathogen. The energy needed to eliminate every single bacterium, spore virus, fungus, mold, etc. it is called dose and is expressed as instantaneous energy necessary to eliminate 99% (or 99.9% or 99.99% …) of the single strain.

Are UV rays effective against Coronavirus SARS-CoV-2?

Specific tests on the UV resistance of Coronavirus Sars-Cov-2 will be available soon. However, there are examples of scientific literature about the UV-C treatment of very similar viruses, such as that of Sars-1 or Mers. There is also evidence of the effectiveness of ultraviolet rays in the disinfection of air and surfaces from microorganisms much more complex and difficult to eliminate than this virus, such as C. Difficile, MRSA, or even more deadly threats, such as Ebola and Legionella. It is estimated that the Sars-Cov-2 virus can survive on surfaces for up to nine days, based on its similarity to Sars and Mers.

Standard disinfectants are effective against Sars-Cov-2, but to provide additional protection and defend against errors in the manual disinfection process, ultraviolet light can be used to disinfect surfaces and equipment following manual disinfection. UV technology is therefore a valid tool in the fight against H1N1, Sars, Mers and now also Covid-19.

UV DOSE REQUIRED EXPRESSED IN mW / CM2 SEC 99% ABATEMENT

| Bacteria | |

| Mycobacterium tuberculosisn (TB) | 4300 |

| Escherichia coli ATCC 11229 | 4800 |

| Legionella pneumophila ATCC 33152 | 3200 |

| Pseudomonas aeruginosa ATCC 9027 | 6500 |

| Salmonella ATCC 6539 | 4500 |

| Staphylococcus aureus | 3200 |

| Streptococcus hemolyticus | 4400 |

| Vibrio cholerae | 4100 |

| MRSA | 6550 |

| Clostridium Difficile | 10000 |

| Viruses (generics, DNA and RNA) | |

| Flu virus A | 4558 |

| Hepatitis A HM175 | 8000 |

| Corona Virus (SARS-CoV1 – MERS-Cov) | 1200-1500 |

| Rotavirus | 15000 |

| Molds | |

| Aspergillus Amstelodami | 66700 |

| Aspergillus Brasiliensis (Niger) | 226000 |

| Yeasts | |

| Comuni lieviti dolciari | 12000 |

| Lievito di birra | 12000 |

Light Progress products for environmental disinfection

What are the advantages of Light Progress products for environmental disinfection?

DEEP DISINFECTION IN THE ABSENCE OF PEOPLE

Our UV systems can be switched on continuously in the absence of people (e.g. during the night or during work breaks.) The disinfection of air, machinery and all that which is contained within the environment allows to start the working day in ideal hygienic condition. The microbial load level of a room is therefore kept constantly low.

DISINFECTION IN THE PRESENCE OF PEOPLE

Purification or the integration of UV technology within the conditioning channels in centralized systems allows you to treat the air of an environment, 24 hours a day, without contraindications for the staff present. A real “washing” of the air is thus obtained, lowering the microbial residue after a few minutes, until it is reduced to negligible percentages, in a simple, immediate and safe way and without the slightest contraindication.

IMMEDIATE EFFECT

For effective treatment (99.9% killing of bacteria) takes just a few minutes. All our products are sized in such a way as to guarantee safe results in certain and rapid times. After the treatment, the objects are immediately reusable, the rooms do not need to be ventilated, the surfaces have no residue.

NO DANGER OF DISPERSION OF GLASSES

With the special UVLON protection, the original and unique optional solution of Light Progress. No danger of dispersion of glass fragments from a possible breakage of the UV-C lamps.

SAFE, CONVENIENT, AND ECONOMICAL

The treatment is immediate and ready for use. Maintenance is minimal with low costs of both energy and service consumption. UV rays do not pass through the materials and are very safe when used correctly. For example, the UV-C wavelength (invisible) cannot pass through any glass, even if the traditional “blue light” of the lit lamp remains visible.

If correctly used, UV rays can lead to abatement results close to sterilization, even if it is more correct to always speak of disinfection or high degree of disinfection.

Direct irradiation in the absence of people

PERMANENT

UV-STICK

It can be easily applied as a common ceiling light, super flexible, versatile and simple to apply.

The UV-STICK series includes a wide range of models of direct irradiation strips, different according to the UV-C powers of the lamp (s) and the material of the case.

The -NX model is in fact in AISI 304 stainless steel; -AL model is made of high quality extruded aluminum, light and solid.

Placed behind the lamp a layer of reflective aluminum mirror bright mirrors the UV rays that are directed towards the surfaces to be treated by optimizing the angle of radiation by increasing the disinfection performance.

Tin to dust and water (IP 55).

UV-STICK

Especially in the case of installation of multiple appliances, UV-STICK can be managed by controlling the operation of switching on, off, security control of entry into the treated room, fault alarm and hour counter.

It is ready for use and requires no special maintenance, except for the periodic replacement of the lamps. It is built entirely in Italy, with high quality and extremely resistant materials.

| uv-SticK | e40H-nX | E75H-NX | e40H-al | e60H-al | E75H-AL |

| Lamp Lifetime (hours)* |

≤ 18.000 | ≤ 18.000 | ≤ 18.000 | ≤ 18.000 | ≤ 18.000 |

| Total Consumption (W) | 40 | 75 | 40 | 60 | 90 |

| External Dimensions Ixsxh (mm) | 530x65x96 | 986x65x96 | 542x80x95 | 705x80x95 | 999x80x95 |

| Weight (Kg) | 1,5 | 2 | 1,4 | 1,7 | 2,2 |

| Treated Volume (m3) | 20 ÷ 40 | 40 ÷ 65 | 20 ÷ 40 | 30 ÷ 50 | 40 ÷ 65 |

| Treated Surface (m2) | 7 ÷ 13 | 14 ÷ 25 | 7 ÷ 13 | 10 ÷ 17 | 14 ÷ 25 |

| Protection Rating | IP 55 | ||||

| Replacement Lamp | CHS-40WH | CHS-90WH | CHS-40WH | CHS-40WH | CHS-90WH |

* Continuous Operation

Direct irradiation in the absence of people

ON WHEELS

UV STICK-ST

The best seller among Light Progress products, UV-STICK-ST is the most compact and cheapest mobile disinfection system on the market. Very useful for the treatment of small rooms, the main features of UV-STICK-ST are:

- 2 18,000- hour lamp positioned on a stand with 4 swivel wheels to facilitate movement.

- All the equipment is in stainless steel.

- Control unit with switch equipped with protection fuse, chronotimer for setting the delay and duration of the ignition, start button and hour counter for replacing the lamps when exhausted.

- UV lamps are protected by a grid

- The body includes reflective walls in mirror-polished aluminium.

| UV-STICK-E2/75H-ST-NX-NT | |

| Lamp Lifetime (hours)* | ≤ 18.000 |

| Total Consumption (W) | 2X75 |

| External Dimensions Ixsxh (mm) | 404x336x1420 |

| Weight (Kg) | 7 |

| Treated Volume (m³) | 50 ÷ 100 |

| Treated Surface (m²) | 15 ÷ 30 |

| Protetcion Rating | IP 20 |

| Replacement Lamp | n° 2 CHS-90WH |

* Continuous Operation

Direct irradiation in the absence of people

MOBILE

UV PENTALIGHT

Designed to provide high quality UV contamination control in any type of environment, the main features of PENTALIGHT are:

- 5 lamps, 360° irradiation.

- Available in 3 sizes.

- Lamp Model (60-90 or 120w) (23 inches, 35 inches or 46 inches – T5 lamps 18,000 hours of lamp life.

- Motion sensor on each side to automatically turn off the lamps if staff enter the room.

- Remote control to turn the system on and off and check the treatment status.

- High quality wheels

- Visual indicators (orange / red / green) to indicate accidental start / stop / end of treatment.

- Can be connected with 1 or 2 UV-PENTALIGHT SHADOW UNITS with a simple cable.

- The positioning of multiple units in different positions allows users to have a single disinfection cycle by treating an entire area.

- The 99.99% treatment must be carried out within 5 minutes. (University tests according to ongoing FDA standards.)

| UV PENTALIGHT | E5/60H | E5/90H | E5/120H |

| Lamp Lifetime (hour)* | ≤ 18.000 | ≤ 18.000 | ≤ 18.000 |

| Total Consumption (W) | 350 | 450 | 600 |

| Lamp Sizes | 600 mm (25.9”) G5 High Output | 894 mm (25.9”) G5 High Output | 1175 mm (25.9”) G5 High Output |

| Protection Rating | IP 55 | ||

| Replacement Lamp | n°5 CHS-60WH | n°5 CHS-90WH | n°5 CHS-120WH |

Direct irradiation in the absence of people

MOBILE

UV PENTALIGHT

For optimal use, it is recommended to position UV system in different positions and thus carry out the treatment by trying to cover the whole area, avoiding as much as possible the shaded areas. To optimize the treatment in a single cycle, completely covering larger areas and / or rooms with many shaded areas, the UV-PENTALIGHT model is available in combination with its SHADOW-UNIT which can be connected with a simple cable.

Each UV-PENTALIGHT MASTER version can be connected to a maximum of two SHADOWs in series, however, the power supply is unique, therefore a socket is enough to have distributed up to 3 systems in one environment.

Direct irradiation in the absence of people

MOBILE

The solution supplied adapts precisely to customers’ needs, based on our know-how and our thirty years of specific experience in the applications of UV technology for environmental disinfection, as well as various tests carried out with university research centers;

Light Progress systems are specific for different uses, inspired by real applications and improved over the decades thanks to a very close relationship with installers and end-users.

Continuous tests are underway at the University of Siena, our excellent research partner.

Air purifiers in the presence of people

LOCAL TREATMENT

UV-FAN is an extremely versatile UV-C air purifier and consists of a load-bearing structure in extruded aluminum and a front cover with micro-holes that allow the entry and exit of the air at the two ends. Conveyed by a silent integrated fan, the air present in the room enters the germicidal chamber of the purifier to be decontaminated by microbes, viruses but also chemical contaminants.

The germicidal chamber houses the UV-C lamps and is built in a special ultra-pure mirror aluminum which amplifies the disinfectant power of the lamps; by passing through it, the air is purified by all microorganisms to be returned to the environment free of contaminants.

Inside the chamber is housed the TIOX®, nano-structured titanium dioxide filter, which in combination with the very high UVC power emitted by the lamps, is an excellent photocatalyst that degrades organic and inorganic pollutants (SOV, VOC volatile organic compounds and NOX, nitrogen oxides) present in the environments.

In addition, the nano particles of TIOX® have a strong oxidizing power and amplify the germicidal effect of UV-C rays on microorganisms.

UV FAN

It can be used, always, even in the presence of people, thanks to the optical labyrinths that hold the UV-Cal rays inside, the silent fan and its low consumption. The possibility of constantly keeping the UV-FAN in operation, even 24h / 24, allows a real “washing” of the air, progressively lowering the microbial residue in the air after a few minutes, until it is reduced to negligible percentages.

The UV-FAN series includes a wide range of wall or wheel purifiers (-ST model), different according to the UV-C powers of the lamps and the dimensions.

| UV FAN | uv-fan- M2/40H | uv-fan- M2/95HP | uv-fan- M2/95HP-ST |

| Dimension LxSxH (cm) | 96x26x13 | 104x32x13 | 123x32x13 |

| Air Flow (m3/h) | 70 | 150 | 150 |

| UV lamps Nr. Power (W) | 2×40 W | 2×95 W | 2×95 W |

| Consumption (W) | 105 W | 220 W | 220 W |

| T.M.L. reduction | >99% | >99% | >99% |

| Irradiation area (m2) (h=m3) | 20 | 40 | 40 |

| Irradiation Volume (m3) | 50 | 100 | 100 |

| protection rating | IP 20 | ||

* Continuous Operation

Air Purifiers

LOCAL AIR TREATMENT AND SURFACE DISINFECTION

UV FAN Bd

UV FAN Bd St

The exclusive BD version (or on BD ST wheels) in addition to the purifier function in the presence of people described so far (operating or daytime phase), provides the possibility of turning on an external integrated UVC lamp to thoroughly disinfect the air and the surrounding surfaces by radiating them directly (in the non-operational or night phase, immediately preceding the use of the premises).

The two ignitions can be managed separately, also by means of a double remote control.

The external lamp can be requested with UVLON-PIPE protection to retain glass fragments in case of breakage.

Air Purifiers

LOCAL AIR TREATMENT AND SURFACE DISINFECTION

UV FAN Bd

UV FAN Bd St

| UV FAN | UV-FAN-M2/95HP-BD* | UV-FAN-M2/95HP-BD-ST* |

| Dimension LxSxH (cm) |

104x40x13 | 123x40x13 |

| air flow (m3/h) |

150 | 150 |

| UV lamps Nr. Power (W) |

2×95+55 W | 2×95+55 W |

| Consumption (W) |

220+55 W | 220+55 W |

| T.M.L. reduction |

>99,9% | >99,9% |

| Irradiation area (m2) (h=m3) |

40 | 40 |

| Irradiation Volume (m3) |

100 | 100 |

| protection rating |

||

* Continuous Operation

Air Treatment

Centralized

UV DUCT

It is a disinfection system for HVAC that adapts to small spaces, even for retrofit applications installed inside the air conditioning ducts, or in the final sections of the Air Treatment Units (U.T.A.) directly from the outside. It creates a UV-C barrier that inhibits the proliferation of viruses, bacteria, molds, spores, very harmful to health, which commonly nest within the Air Conditioning.

It manages to treat the air flow that passes through its lamps, eliminating the bacterial load and the dispersion and distribution of dangerous and annoying pathogens in buildings. It inhibits the creation of biofilm on internal surfaces, the result of the presence of microorganisms and conditions favorable to their proliferation present in AC systems, such as temperature changes, high levels of humidity and darkness.

The increase in indoor air quality allows a consequent and general improvement in comfort but, more specifically, the use of UV-DUCT-FL eliminates important problems (such as Legionellosis, Tuberculosis, Influenza, etc.) but also as ” Sick Building Syndrome “,” Monday Fever “, promotes the control of high hygiene standards in the Food Industries and, in the health sector, that of dangerous Infections Related to Assistance (ICA).

In addition to the numerous health benefits, the use of UV-DUCT-FL allows important benefits in terms of running costs of the A.C. system, which is sanitized and remains clean without the need for continuous and expensive maintenance.

The UV-DUCT-FL series includes a series of flange modules from which two “U” lamps of different lengths (from 20 to 50 cm) and powers (from 70 to 90 W) emerge, protected by a stainless steel grid. The main features of UV-DUCT-FL are the super compact measurements and onboard controls, which allow an effective application even in existing air conditioning systems (retrofits).

It is installed by making two holes at the point of the A.C. channel, using the practical template provided. After inserting the lamps in these holes, it is only necessary to screw the flange directly to the duct, press the switch and you’re done. Specific ballasts are inserted directly inside the case to power the UV-C Light Progress lamps, optimizing their performance and durability.

| UV-DUCT-FL | 2/35HP | 2/60HP | 2/95HP |

| Lamp Lifetime up To (hours)* | ≤ 18.000 | ≤ 18.000 | ≤ 18.000 |

| Consumption (W) | 70 | 120 | 190 |

| Dimensions Ixsxh (mm) | 410x130x278 | 410x130x477 | 410x130x603 |

| “A” Lenght (mm) | 183 | 382 | 508 |

| Weight (Kg) | 2 | 2 | 2,5 |

| Air Flow (m3/h) | 1.000+2.400 | 1.300+3.400 | 2.200+5.600 |

| Protection Rating | IP 20 | ||

* Continuous Operation

Air Treatment

As you can see from the graphs, which are found in the “Study on UV-FAN M1 25 efficacy by Siena Univ. – IT_Rev1 c. stamp and signature”, the microbial reduction percentages are 99.99% for bacteria and 99% for viruses at each step of the air inside the germicidal chamber.

The solutions provided adapt precisely to customers’ needs, based on our know-how and our thirty years of specific experience in applications UV technology for environmental disinfection, as well as several tests carried out with university research centers.

Further tests are underway at the Institute of Hygiene of the University of Siena.

Light Progress is also recognized as a leader in the design and manufacture of UV systems. It is one of the leading companies registered with the International Ultraviolet Association (IUVA), a world-renowned and agency to which the best UV producers are entrusted for the definition of high-quality standards and scientific recognition.

Light Progress is certified ISO 9001, ISO 13485 and is registered with the FDA and EPA.