LAF tech trusted to deliver essential BIO-Decontamination services at Australia’s Vaccine Sterile Manufacturing Facility.

LAF tech specialists deployed TOMI Steramist Systems throughout the facility. Gaseous Ionized Hydrogen Peroxide solution was disbursed via twenty one points of injection throughout the 3000m2 target zone. The Gaseous concentration dwelled within the target zone for thirty minutes only. Aeration and extraction process followed to return the facility back to a safe occupied zone. Safety was assured throughout the process via Monitoring for safe gaseous airborne concentration. NATA calibrated Drager sensors were utilised for this purpose. Process Efficacy was validated to an effective 6- log Kill against the introduced industry standard Geobacillus Stearothermophilus laden SS Biological Indicators.

LAF tech have been performing Facility BIO Decontamination since 1987.Our Validated services and supply of Contamination control equipment have seen our client base expand through out the Life Sciences and Healthcare sectors. Our clients include State and National Quarantine Bio Security facilities PC3-PC4 and GMP Pharmaceutical facilities.

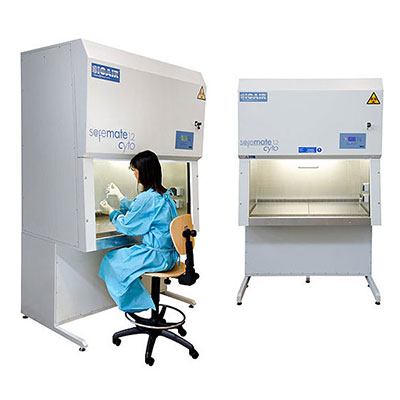

Cutting Edge Solutions for Decontamination Professionals

H202 automated & remote controlled fogging disinfection and decontamination systems.

- Able to safely treat multiple spaces simultaneously

- Less down time than competing less effective technologies

- Precise measurement of H2O2 disbursement

- Pre-conditioning of area not required

- Excellent materials compatibility

- Non corrosive application

LAF Technologies is proud to represent the TOMI range of decontamination systems here in Australia. Our company has been utilising TOMI Steramist technology with supply, technical support, chemical supplies and in field Bio-Decontaminations for over a decade.