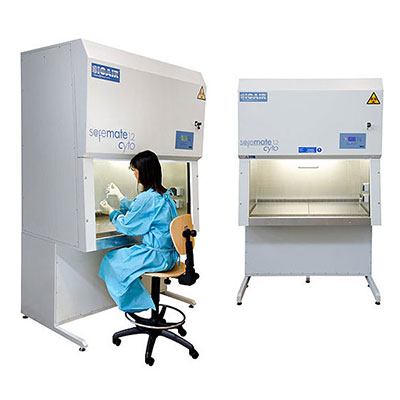

laftech has successfully completed the supply, installation, and commissioning of a high specification TIMOTEC 5 glove sterile environment isolator at a leading RNA research and manufacturing facility in New South Wales.

The isolator has been installed to support critical aseptic processing activities associated with RNA based products intended for upcoming clinical trial applications. The system provides a controlled Grade A environment designed to minimise contamination risk during sensitive manufacturing operations.

System Design and GMP Capability

The TIMOTEC 5 glove isolator incorporates an integrated Vaporised Hydrogen Peroxide (VHP) decontamination system, supporting effective surface sterilisation and robust contamination control. The isolator is engineered to meet stringent GMP requirements for sterile processing environments.

The system configuration has been designed to support consistent environmental control and repeatable decontamination performance, providing confidence for regulated life science and pharmaceutical manufacturing workflows.

Delivery, Installation, and Commissioning

To meet critical project timelines, the isolator was airfreighted from Europe and delivered directly to site. laftech’s specialist technicians completed onsite assembly, installation, testing, and commissioning immediately upon arrival.

Careful coordination and planning ensured the installation was completed efficiently while maintaining strict contamination control requirements throughout the process. All works were carried out in line with project specific protocols and site requirements.

Testing, Calibration, and Ongoing Support

The isolator will undergo NATA testing, with ongoing sensor calibration and routine performance verification to support continued compliance. laftech’s factory trained engineers will provide ongoing servicing, calibration, and preventative maintenance to ensure long term reliability and consistent system performance.

This ongoing support framework provides clients with confidence in regulatory readiness and equipment integrity over the operational life of the isolator.

Supporting Advanced Life Science Manufacturing

This project demonstrates our capability to deliver complex GMP compliant containment solutions under compressed timelines for advanced life science and pharmaceutical applications. We continue to support research and manufacturing facilities across Australia with precision engineered contamination control systems and long term technical support.

Contact Us

To learn more about laftech’s isolator solutions, GMP compliant containment systems, and ongoing service and support capabilities, please contact our team or have a look at our range of Isolators down below:

LinkedIn: LAF technologies Pty Ltd

Ph: 1300 306 002

Web: Isolator Technologies | LAF tech