Understanding Airborne Particle Counters

In environments where air purity is critical, maintaining strict contamination control is essential. Airborne Particle Counters (APCs) are indispensable tools in this process, helping to monitor and ensure the cleanliness of these sensitive environments. In this article, we will explore the two primary types of APCs—Portable and Fixed-Point Remote—and their unique applications, benefits, and considerations.

But what are Airborne Particle Counters?

Airborne Particle Counters are specialised devices designed to detect and measure the concentration of particles in the air. These particles can range in size, and their presence can compromise the cleanliness and safety of environments where strict air quality standards are required, such as in cleanrooms, pharmaceutical manufacturing, and medical device production.

Types of Airborne Particle Counters

Portable APC’s

Portable APCs are versatile, self-contained devices designed for easy transportation and fast air quality assessments. They are ideal for facilities that require flexible monitoring solutions, such as conducting spot checks or moving between different areas within a cleanroom. Some features include:

- Built-in user interface for easy operation

- Internal air sampling system with filtered exhaust

- Can operate on batteries or AC power

- Available in various sample flow rates to suit different needs

Types of portable APC’s include:

- Handheld APCs: Compact with low flow rates (0.1 CFM or 2.83 LPM), perfect for quick, localized checks.

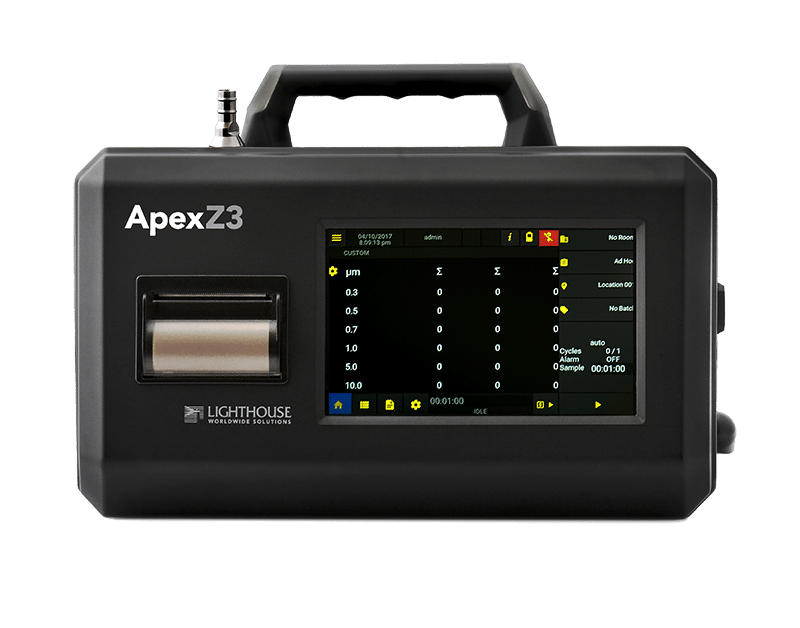

- Standard Flow APCs (ApexZ3): The most common type, with a flow rate of 1.0 CFM (28.3 LPM), suitable for general cleanroom operations.

- High Flow APCs (ApexZ50): Featuring flow rates above 1.0 CFM, these are ideal for large-volume sampling and are often used in cleanroom certification testing.

Fixed-Point Remote APC’s

Fixed-point remote APCs provide continuous monitoring at critical locations, making them indispensable for environments where consistent air quality is vital to product integrity. These smaller, more robust devices are often integrated into process equipment or mounted on cleanroom walls. Some features are:

- Continuous monitoring of specific locations

- Data logging or transmission to external systems like Building Management Systems (BMS) or Facility Monitoring Systems (FMS)

- Less invasive and more durable than portable units

Types of Fixed-Point Remote APC’s inlcude:

- Fixed-Point Remote APC’s with Built-In Pumps (Apex R3p): These units have built-in sample handling systems via pumps or blowers, along with the necessary filtration for all air exhausted from the unit. They are larger, louder, and more expensive than units without pumps but do not require a facility-wide vacuum pump and distribution system.

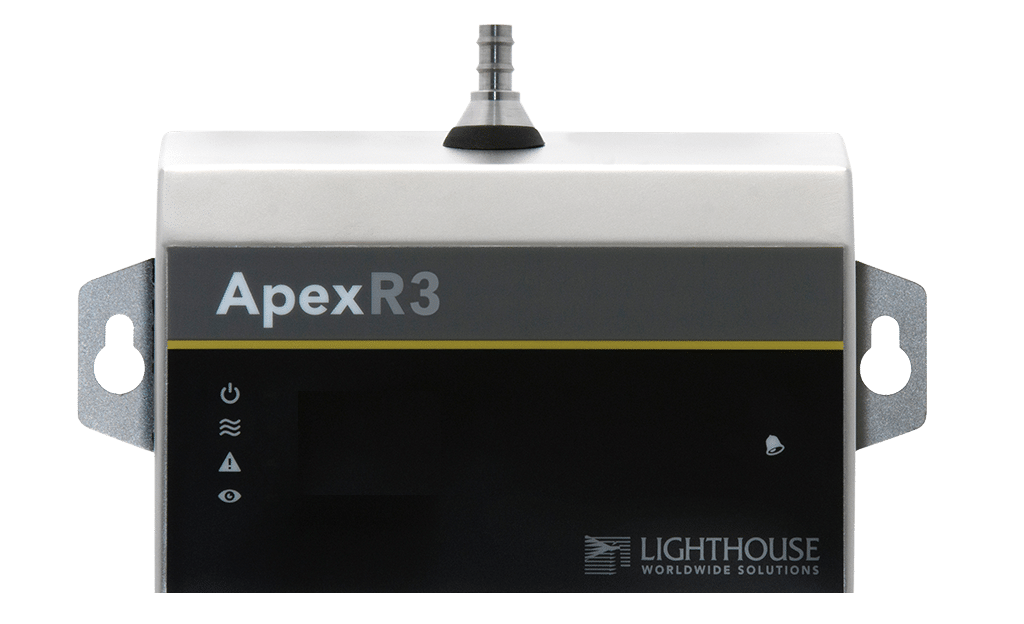

- Fixed-Point Remote APC’s without Pumps (Apex R3): These units require an external vacuum source and are smaller, quieter, and less expensive than units with built-in pumps. They have lower service costs because there are no filters or small pumps to maintain. However, the supporting facility-wide vacuum pump and distribution system require regular service and must provide adequate flow and vacuum for the APCs to operate correctly.

Your Specific Needs

Selecting the appropriate type of APC depends on your specific requirements:

- Portable APCs are best for flexibility and mobile use, offering various flow rates for different contamination control scenarios.

- Fixed-Point Remote APCs are ideal for continuous, location-specific monitoring, ensuring long-term air quality maintenance in critical environments.