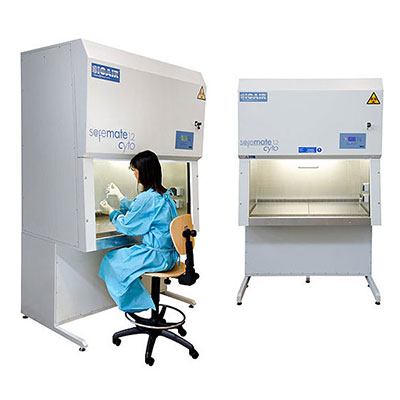

Installation of VHP Decontamination Chambers at Vaccine GMP Facility

The LAF Tech engineering team is finally on-site installing and commissioning Vaporized Hydrogen Peroxide (VHP) decontamination chambers at the Vaccine GMP facility in Melbourne Australia. These state-of-the-art chambers manufactured by our partners at Block Isolator Technology are designed to enhance the sterility and cleanliness of the facility, meeting stringent regulatory standards. Certainly, more details to come as we progress on-site into Validation, IOQ protocols.

Key Features and Specifications:

- VHP Generator Integration:

- The decontamination chambers are integrated with advanced VHP generators, ensuring effective and efficient sterilization.

- Design and Build:

- The pass-through cabins are designed to be fitted onto walls that separate individual rooms, facilitating ease of transfer while maintaining sterility.

- Constructed with high-grade materials: jacket material is stainless steel AISI 304, and the pass-through chamber is made from AISI 316L with a 3.00 mm thickness, polished to a surface finish of Ra < 0.6 µm.

- Rounded corners with a radius of 55 mm for enhanced cleanliness and safety.

- Standards Compliance:

- The lock system complies with the leak tightness classes pursuant to ISO 10648-2.

- Maintains “B” class cleanliness in accordance with the EU GMP Standard, ensuring high hygiene levels.

- Advanced Control System:

- An electronic control system managed by Siemens PLC offers automatic adjustment of basic operating modes.

- Equipped with color touchscreen controls for user-friendly operation.

- Functional Features:

- Mobile perforated shelves enable thorough sterilization of products from all sides.

- The process operates at normal temperatures (approximately 25 to 30 °C) and normal pressures, making it suitable for a wide range of applications.

- Inlet and outlet H14 HEPA filtration ensure high-efficiency particulate air filtration.

- Operational Efficiency:

- The decontamination cycle can be validated, and data can be recorded on various units including a recording unit, printer, or PC.

- The system boasts low operating costs and quick decontamination cycles, ensuring minimal downtime.

- Designed for long operational life with minimal maintenance demands.

- Easy handling and operation further contribute to the efficiency and user-friendliness of the system.

Benefits:

Enhanced Sterility: Ensures a sterile environment crucial for vaccine production.

Efficiency: Quick decontamination cycles and low operating costs improve overall facility productivity.

User-Friendly: Advanced electronic controls and easy handling make the system accessible for operators.

Durability: High-quality materials and construction ensure long-term reliability and minimal maintenance.

This installation underscores LAF Tech’s commitment to providing cutting-edge sterilization solutions that meet the rigorous demands of GMP-compliant vaccine production facilities.