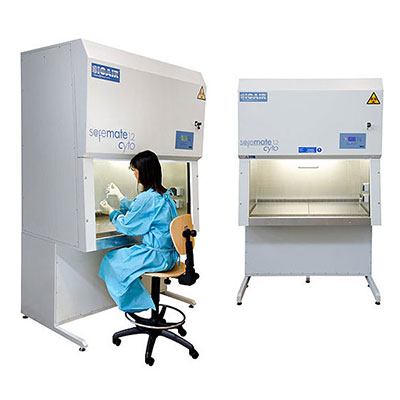

LAF tech is proud to introduce its latest generation VHP (Vaporised Hydrogen Peroxide) decontamination technology, developed in collaboration with DSE USA.

Our VHP System

This advanced system delivers precise, controlled VHP at a concentration of 300 ppm, maintained over a 45-minute exposure cycle to ensure thorough microbial inactivation. The system can achieve peak concentrations beyond 600 ppm, pushing performance beyond conventional gaseous cycles.

The system features a preheat humidity cycle and continuously monitors both temperature and humidity to maintain optimal decontamination conditions throughout the process.

This next-generation H₂O₂ decontamination system offers a safe, effective alternative to many traditional methods—without the use of harsh, volatile, corrosive, carcinogenic or toxic chemicals.

Validated, Controlled & Reliable

Our decontamination process (SOP) has been fully validated and verified using the following:

- Vaisala PEROXCAP® HPP270 H₂O₂, temperature & humidity probe for accurate real-time monitoring and data logging

- Geobacillus stearothermophilus Biological Indicators (BIs) to verify sterilisation efficacy

- Chemical and Enzyme Indicators to provide immediate onsite visual confirmation of cycle performance

All protocols comply with local and international regulatory standards, ensuring reliable, repeatable, and audit-ready results for:

- Bio-containment facilities

- Pharmaceutical manufacturing

- Biomedical labs and cleanrooms

Contact Us Today

Speak with the LAF tech team to discuss our Technology and Detailed processes in line with your facility’s requirements for: