Compliance Starts with LAF tech

At LAF tech, we understand that not all particle counter calibrations are the same. Our latest white paper explains why following the ISO 21501-4:2018 standard requires more than a simple performance check – and why choosing the wrong calibration partner can compromise your compliance, your product quality, and your data integrity.

Why the Standard Matters

ISO 21501-4:2018 sets the calibration and performance requirements for light-scattering airborne particle counters, which are critical in cleanrooms, pharmaceutical manufacturing, and other contamination-sensitive environments. Accurate, repeatable, and traceable data is essential, but achieving it depends on how the calibration is performed and by whom.

The Problem with Third-Party Calibration

Many service providers offering calibration do not have access to OEM proprietary calibration software, firmware updates, and internal procedures. Without these, they are unable to replicate the manufacturer’s full calibration process and can only perform partial checks or basic adjustments.

This limited approach creates a false sense of compliance, leaving organisations vulnerable to hidden performance issues and undetected measurement errors. Over time, these inaccuracies can accumulate, resulting in misleading particle count data that directly affects cleanroom validation, contamination control measures, and batch release decisions.

The LAF tech Difference

Read the Full White Paper

As an ISO 17025 NATA-accredited laboratory with full OEM authorisation, LAF tech delivers a level of calibration service that goes far beyond routine checks. Our accreditation demonstrates that every process we follow has been independently assessed for technical competence, traceability, and compliance with international standards, a guarantee that our clients can rely on.

Because we maintain direct partnerships with leading global instrument manufacturers, we have complete access to original calibration algorithms, manufacturer-specific procedures, and the latest firmware updates. This allows us to perform full “as found” to post-adjustment calibrations, ensuring that every instrument is not only verified but restored to optimal performance according to the manufacturer’s precise specifications.

We issue valid calibration certificates that auditors and regulatory bodies recognise without question. These certificates are backed by meticulous documentation, making compliance verification faster and smoother during audits.

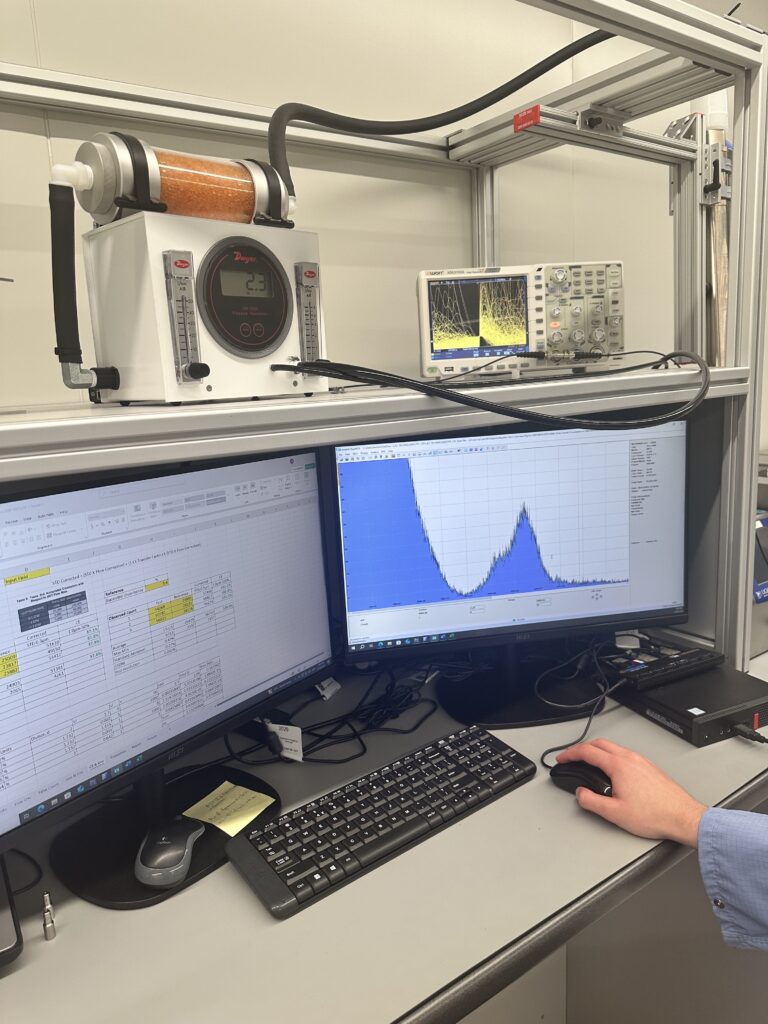

To maintain the highest level of accuracy, repeatability, and traceability, we conduct regular interlaboratory testing with Lighthouse Worldwide Solutions. This 1:1 comparison process validates not only the performance of our calibration systems but also the skill and competence of our technicians. The result is absolute confidence in the integrity of the data your particle counters produce.

This comprehensive, fully validated approach means our clients receive true calibration, not just verification. It’s why leading pharmaceutical companies, GMP-compliant manufacturing facilities, research organisations, and healthcare institutions across Australia and New Zealand consistently choose LAF tech as their trusted calibration partner.

Our white paper breaks down exactly why OEM-authorised calibration is essential, the risks of incomplete calibration, and how LAF tech safeguards your data integrity.

For more information on our calibration services, contact: